Pharmaceutical shipments are sensitive to temperature variations throughout an extensive and complex supply chain. Resolving the interdependent logistic issues along the supply chain can significantly reduce the resulting costs. Creating a solution that reflects each stakeholder’s perspective along the supply chain can make this solution both affordable and sustainable. The presented approach provides a smart solution using the Internet of things (IoT) for safeguarding pharmaceutical shipments through the entire international supply chain journey.

Authors: Mohammad Shakhatreh & Brett Fifield

Phase One: Identifying the problem through empirical analysis

Insights gained from managing pharmaceutical shipments at the cargo terminal of Amman airport revealed just how sensitive pharmaceutical shipments were to extreme temperatures experienced during international shipments. A six sigma approach was used to identify and eliminate the root causes of these temperature excursions and modify the shipping process accordingly.

Research on supply chain data revealed that 20% of all temperature-sensitive shipments arrive at their final destination damaged. Indeed, an IATA (Air Cargo News 2019) study found the pharmaceutical industry losses US $35 billion year from such damage, and that 30% of all temperature excursions occur during transit within airports. Further research found no comprehensive solutions currently available.

The study had two primary objectives: 1) thoroughly investigate the problem, quantify its impact and find its root causes, and 2) to develop a viable and scalable solution that would amass investor funding for creating a startup company (Shakhatreh 2020). A comprehensive solution would require validation from all stakeholders throughout the entire supply chain. Funding for implementation required validation by customers, stakeholders, and venture capitalists.

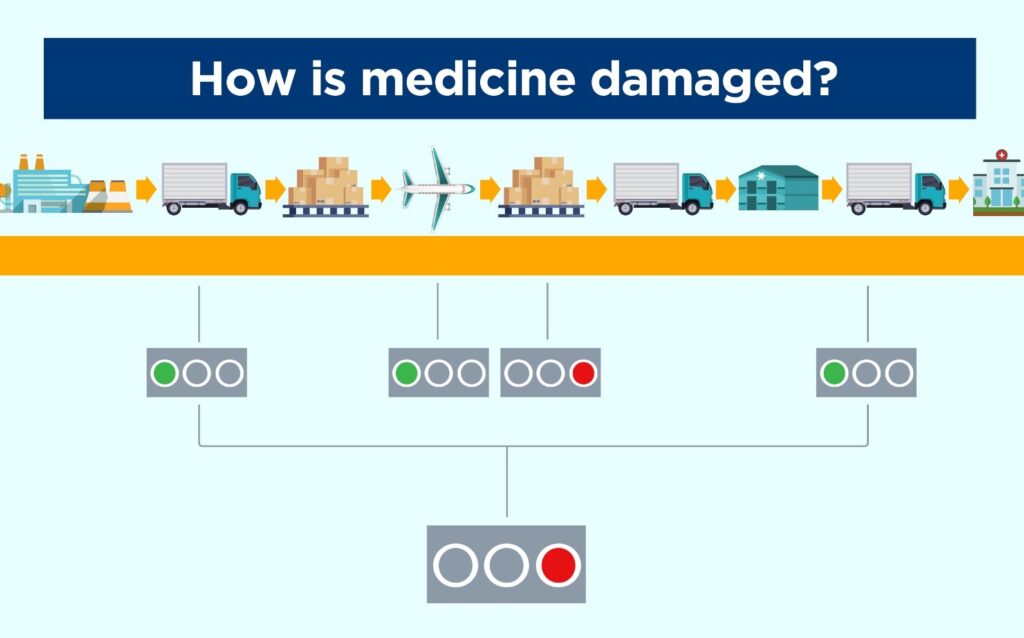

The source of the problem was identified as a highly interdependent, international supply chain involving many stakeholders. Figure 1 illustrates the airfreight shipment journey between the pharmaceutical supplier and final customer, with each stage managed by a separate stakeholder. This supply chain includes many risky touch points, each without environmental cooling systems. Shipments are temporarily exposed to a wide temperature range that often exceeds the limitations of the medications being transported. A lack of efficiency at any one of these links can create a temperature excursion that damages the shipment.

Figure 1: A supply chain journey with multiple transitions across transport types (WHO 2015).

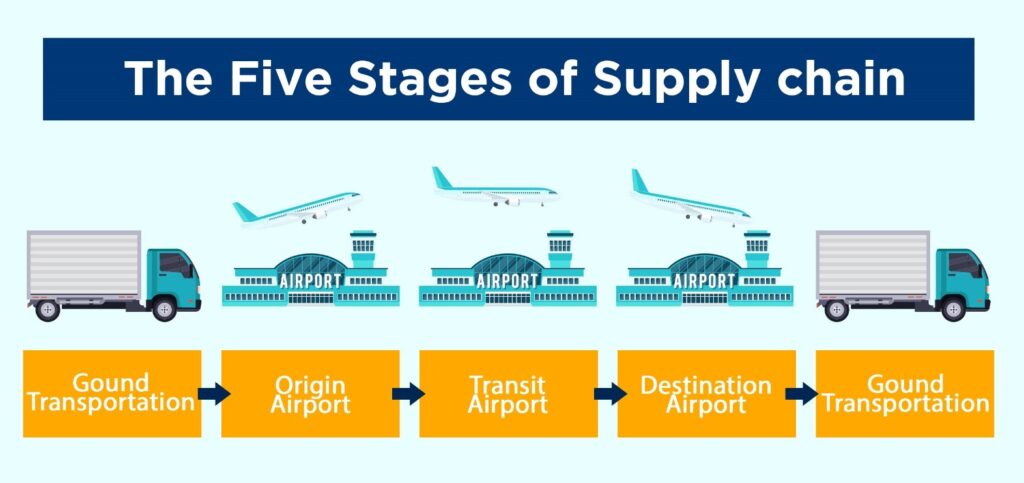

Figure 2 illustrates the five basic stages of an international airfreight supply chain journey. Empirical analysis revealed how most of the recorded temperature excursions occurred within airports.

Figure 2: Generic stations within a typical international transport process (WHO 2015).

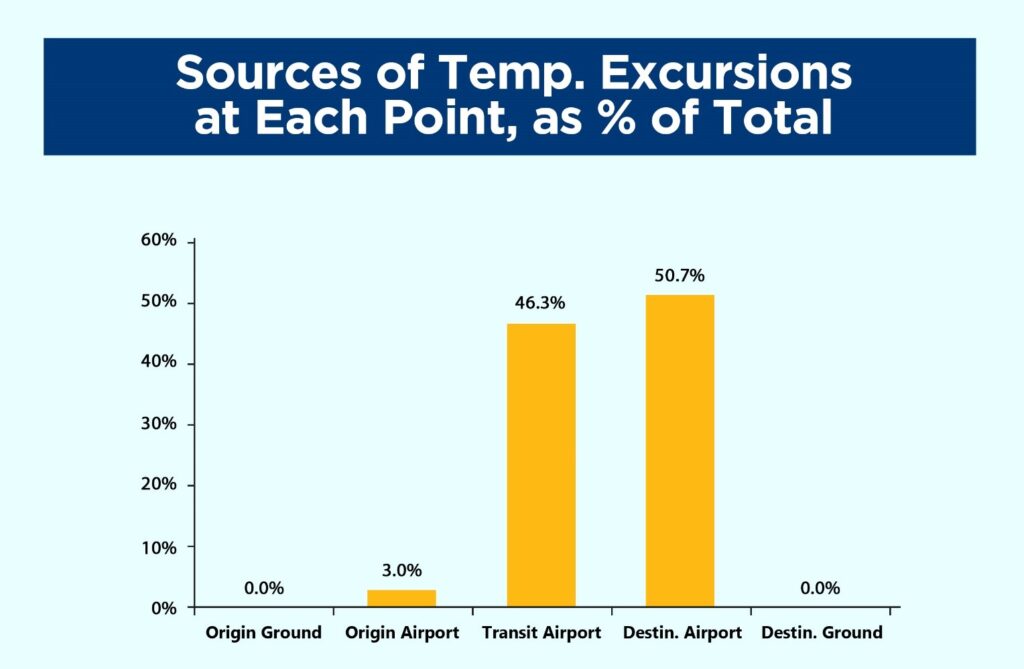

Data was then recorded for 96 shipments arriving in Amman, Jordan, from January 19 to August 19, 2019. Of these, 58 shipments were exposed to temperatures that deviated too far from allowable tolerance. Figure 3 reveals how all temperature excursions in this sample occurred within one of three airport stages in the supply chain, and that no excursions occurred during the ground transportation stage. This verified that uncovering the root causes of these temperature excursions required a focus on touch points inside airport properties.

Figure 3: Incidence of excursions across the international supply chain (Shakhatreh 2020).

Phase Two: Using six sigma insights to co-create a solution

Six sigma management tools were employed to identify the problematic logistical steps within the supply chain. Unique observations from meetings with stakeholders were collated, revealing that the problem was primarily a shortage of ground transport equipment and cold storage facilities at airport properties, as well as a shortage of manpower in airfreight handling and customs activities. For example, 80% of all pharmaceutical shipments arrived at the cargo terminal between 11am and 2pm. There was insufficient equipment and manpower during this peak cargo handling time to adequately protect the sensitive pharmaceutical shipments. The resulting congestion caused medicines to be held in inappropriate storage areas before being delivered to cold storage facilities.

Another root cause of this congestion was that airport regulations allowed ground shippers to drop off cargo up to 48 hours prior to flight departure times. Most shippers saved costs by consolidating ground shipments by increasing batch sizes to be processed during peak cargo times. For example, week day freight handling at airports often peaked on Thursdays. It was discovered that Fridays were often holidays in those regions along the supply chain, and most pharmaceutical shippers found it economical to combine planned weekend shipments with Thursday shipments.

Phase Three: Peer Review and Financial Validation

The root cause of temperature excursions within airport properties was created by the preferred delivery practices of ground shippers, combined with the resource limitations of freight handling logistics of the airport. A cost-effective and coordinated shipment process was co-created with the independent stakeholders. It utilized newly available technology that provides an active monitoring capability (rather than existing passive technology) to follow pharmaceutical shipments.

A temperature monitoring, geo-positioning device was identified that could be modified to provide real-time reporting of data using the connectivity characteristics of the Internet of Things (IoT). The optimal logistics of processing this valuable information could be distributed and verified across all of independent stakeholders. Multiple meetings with these stakeholders resulted in a plan for properly handling and returning these reusable devices back to the beginning of the supply chain.

This plan has been successfully pitched as a business module to investors and venture capital juries at many startup competitions around the world, winning first place at an IoT hackathon recently held in Jordan. It also won second runner up at an MIT startup competition and won first place out of 60,000 applicants at a Startup Turkey compaction held in Istanbul.

References

Air Cargo News. 2019. Failures in temperature-controlled logistics cost the biopharma industry billions. [Cited 12 Nov 2019]. Available at: https://www.aircargonews.net/sectors/pharma-logistics/failures-in-temperature-controlled-logistics-cost-biopharma-industry-billions/

Shakhatreh, M. 2020. Safeguarding Pharmaceutical Shipments Using the Internet of Things. Master’s Thesis. LAB University of Applied Sciences. [Cited 8 May 2020]. Available at: http://urn.fi/URN:NBN:fi:amk-202002162452

World Health Organization (WHO). 2015. How to monitor temperatures in the Vaccine supply chain. WHO Vaccine Management Handbook, VMH-E2, 1-44.

Authors

Mohammad Shakhatreh is studying in the International Business Development program at LAB University of Applied Sciences.

Brett Fifield is a Principal Lecturer of International Business at LAB University of Applied Sciences.

Illustration: https://pxhere.com/fi/photo/50720 (CC0)

Published 8.5.2020

Reference to this article

Shakhatreh, M. & Fifield, B. 2020. Solving logistic problem using six Sigma and co-creation. LAB Pro. [Cited and date of citation]. Available at: https://www.labopen.fi/lab-pro/solving-logistic-problem-using-six-sigma-and-co-creation/